- Airtightness Testing

- Automated Assembly Line for Oil Pan

- Vacuum booster assembly line

- New energy motor assembly production line

Productions

the cases

Service and Support

Products

Industries

Service

Intake manifold assembly line

Intake manifold assembly line

Intake manifold assembly lineIntake manifold assembly line

1.It can be distributed in L shape or U shape according to site requirements.

2.The total area of the equipment: 11500mm*1500mm; the equipment height is 2200mm and the operating height is 900mm.

3.Each workstation uses manual transmission power, and the whole line needs 3-4 operators.

4.The layout of the line is rational, aesthetically pleasing, easy to operate, and reliable in performance.

5.The lower frame is welded with square steel, and the upper frame is made of aluminum profiles. Safety protection devices are arranged around the frame. The color is beige white, and the equipment protection level is 5.

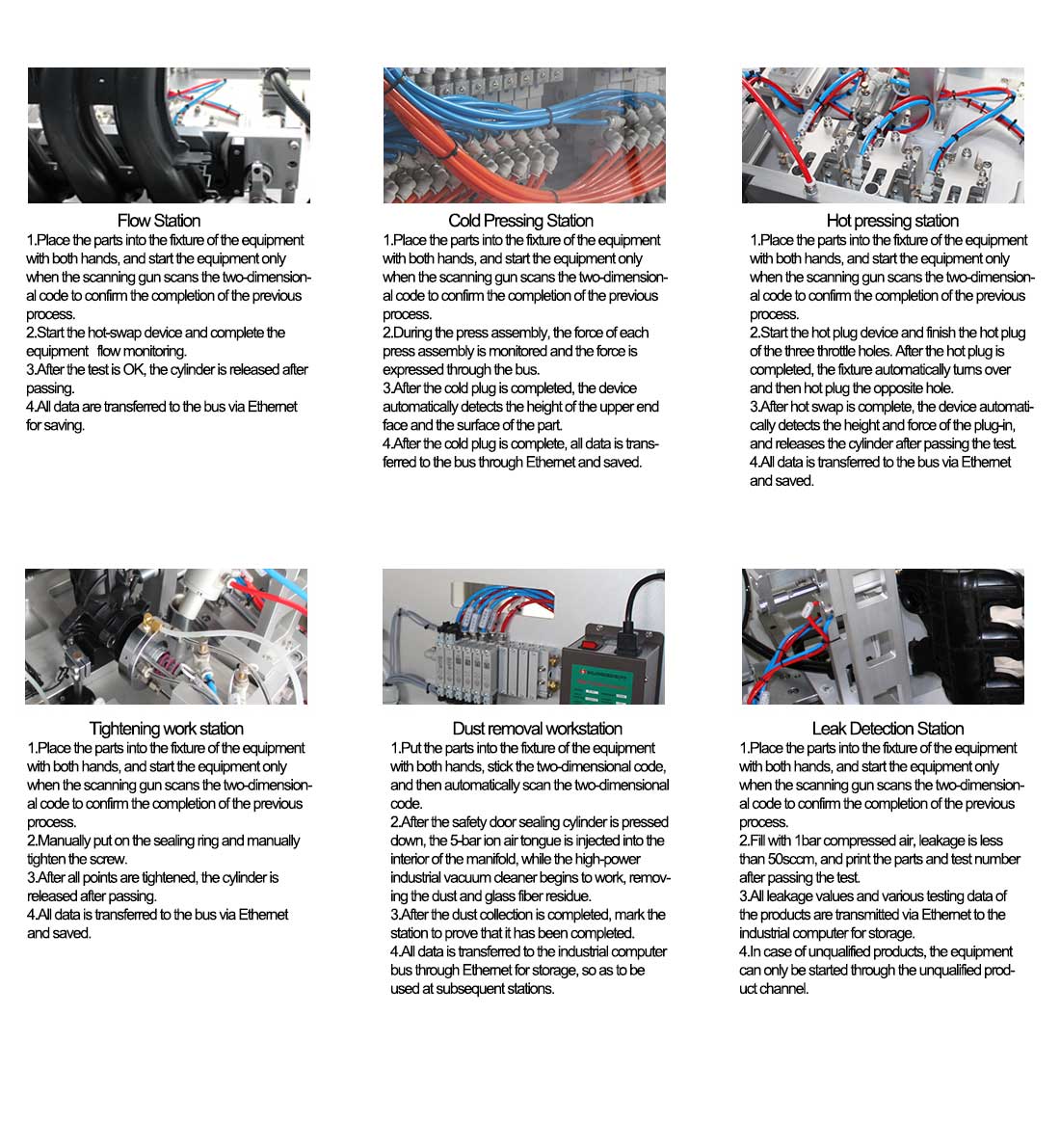

6.The workstations are as follows: Flow - cold pressure - hot swap 1- hot swap 2- hot swap 3- tightening 1- tightening 2- dust removal - leak detection - bus.

7.Control System: Bus control system, all the data has a unified control console storage. Each station transmits data to the bus through TCP/IP, which brings great convenience to equipment maintenance and monitoring.

8.If the equipment effectiveness is not verified before the start of the shift, the equipment will not operate normally.

Monitoring System: Monitor the current status of each station in real time, and create work logs for each station. Users can trace the working status of the station through the station log, including alarm, work start time and work end time, etc.

Interactive System: The data traceability system interacts with the station in real time to ensure that the products at the current station are qualified products tested at the previous station, otherwise the current station is not allowed to produce; After the test is completed, the interactive system saves the test data in time.

Data Traceability Function: The data traceability system allows for querying produced workpiece through their barcode, production date, or other indexing methods, achieving the purpose of data traceability.

THE CASES

PROFESSIONAL

TECHNOLOGY

Reason for the choice of many customers

Upton Automation Systems (Guangzhou) Co., Ltd. Upton Automation Systems (Kunshan) Co., Ltd.

address:Rm.101&201, Bldg-1, No.19, Yunpu 1st Road, Huangpu District, Guangzhou, Guangdong, China, 510530

address:No.8 Xutang Road, Qiandeng Town, Kunshan, Jiangsu Province, China, 215343